In the hands

of a watchmaker

Zurich

© Cosa

© Cosa

All eyes are riveted on one pair of hands, trembling slightly in the stiff sleeves of a white coat. Inexperienced but willing fingers carefully assemble the components, pieces so tiny that they seem too fragile to touch. Foreheads wrinkle as everyone focuses their gaze on the minute mechanical movements, and then the crucial moment: using the famous watchmaker’s magnifying glass along with a screwdriver and precision tweezers. Yes, this is how watches are made.

Building a watch from scratch is something almost anyone can do but isn’t something anyone should do on their own. And with Cosa, you don’t have to. How do I know? Because I’ve been there and done that. As a child, I watched my grandfather take out his pocket watch, open it and tell the time. So you can imagine my excitement when I got to be part of a watchmaking workshop in Zurich.

Watch heaven

Watch heaven

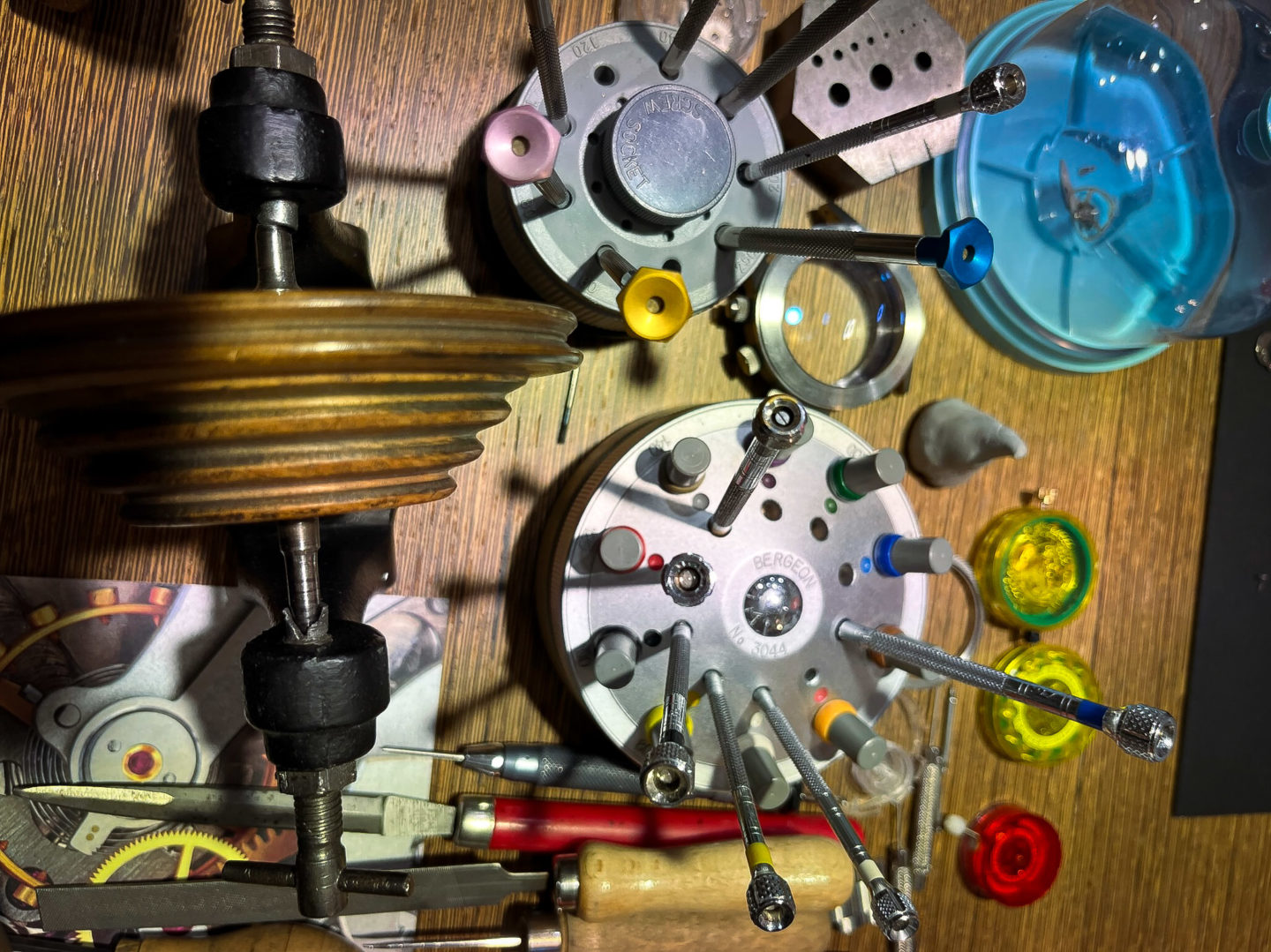

From the moment I pushed open the workshop door, I was in horological heaven, surrounded by anything and everything to do with making time: watches in all manner of models and colours, leather plates, sketches, boxes with compartments full of microscopic parts, mechanisms of all kinds. It was an Aladdin’s cave of timepieces and the pieces needed to create them. And then our host invited us to sit around a table.

Timepiece experience

This friendly, calm man welcomed us into his world, telling us the story of the family brand, its key moments and a few anecdotes. He’s rightly proud of the success of this business and we were about to gain personal insight into the key to that success. It was time to get down to the heart of the matter: the Art of Watchmaking. This one was going to be a team effort in the fine art of creating an object as delicate, aesthetic and meticulous as a watch.

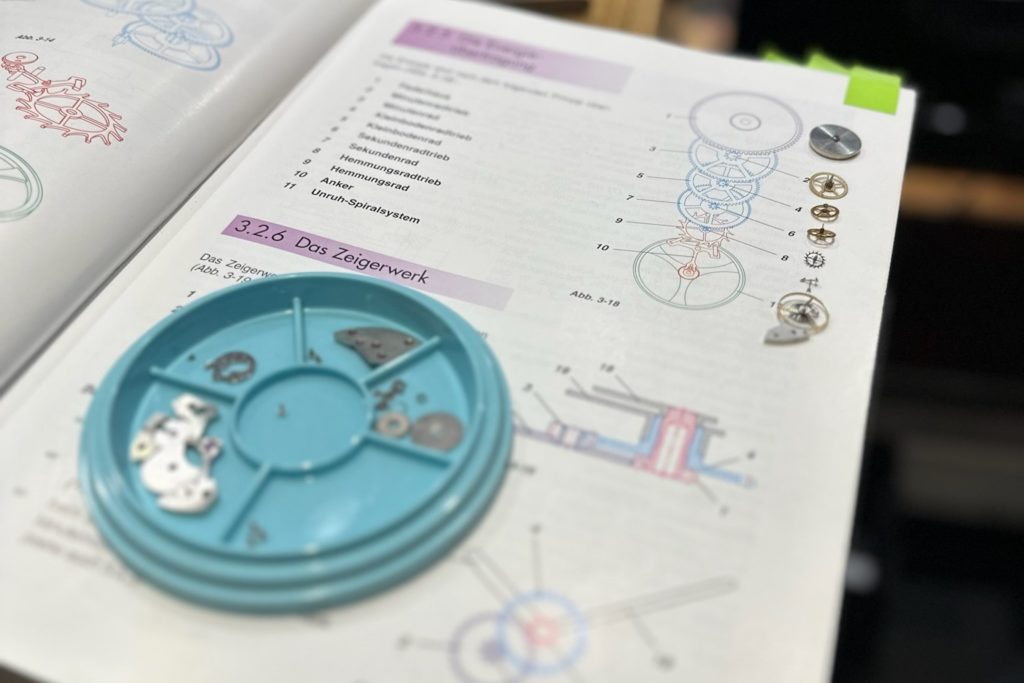

During the first part of the workshop, silence reigned. We carefully observed our watchmaker’s every move, eager eyes following his nimble fingers as they went about their work. Not forgetting learning all the new technical words that we’d need to remember later, when we did this ourselves. It was full-on concentration, and it was wonderful.

Team work

Team work

Next, we were each invited to put on a white watchmaker’s smock: you can’t make a watch if you don’t look the part. As a team, we had to assemble a watch, taking it in turns to be responsible for one phase of the process. Nervous laughter rippled round the room because we all knew how delicate each operation was. Nerves of steel and steady hands were essential.

Palpable tension reached its height as we proceeded methodically through the various stages. Each of us felt a certain pride in our personal prowess, and by the end, it seemed that nobody wanted to leave. We had done what we set out to do: we had made a watch, and one that worked. A team effort carried out with joy and good humour, but also with immense gratitude for the invaluable technical lessons shared with us.

I’ll never look at a watch in the same way again. On the surface, it’s such a simple thing – a way to tell the time. But behind that are the intricate mechanisms needed to achieve that simple thing, mechanisms that need expertise and, yes, time to put them together.

By the way, we also offer watchmaking workshops in other Swiss cities so please contact us for more information.